If you work in an industrial facility, you have probably come across bag filters at some point. These essential filtration devices play a vital role in maintaining clean and safe working environments. Bag filters capture and remove contaminant particles from gas or liquid streams, ensuring the quality of the end product and preventing harm to equipment and people.

But with so many types of bag filters available, how do you know which one to choose for your filtration needs? This ultimate guide on bag filters will provide you with the necessary insights into bag filter types, their function, and efficiency. You will gain an understanding of bag filter design, working principle, and maintenance requirements, enabling you to select the best bag filter system for your facility.

Key Takeaways

- Bag filters capture and remove contaminant particles from gas or liquid streams in industrial facilities.

- The ultimate guide on bag filters will provide an overview of bag filter types, their function, and efficiency.

- Bag filter design, working principle, and maintenance requirements all play crucial roles in selecting the best bag filter system for your facility.

- Choosing the right bag filter system can ensure product quality and safety, prevent harm to equipment and people, improve energy efficiency and reduce emissions.

- Bag filter uses are not limited to a specific industry. They are widely used across various industrial processes and applications.

Understanding Bag Filter Working Principle

Bag filters are widely used in industrial filtration to remove particulate matter from gas or liquid streams. But how do they work? Bag filter working principle revolves around the use of filter media in the form of bags, which capture and retain contaminants within their surfaces.

The filtration process involves two primary stages: capturing the particles and removing them from the system. As contaminated gas or liquid flows through the bag filter, the filter media captures the particles through a combination of mechanisms, including interception, diffusion, and inertial impaction. Once the particles are trapped in the bag filter, they must be periodically removed to maintain efficient filtration.

Beyond the filtration process, several other factors influence the effectiveness of bag filters. These include the selection of filter media, the design of the bag filter system, and the operating conditions. Each of these factors must be carefully considered and optimized to maintain clean industrial environments and prevent contamination.

Overall, understanding the working principle of bag filters is essential for selecting the right filter media and designing an efficient bag filter system. By capturing and removing contaminants from gas or liquid streams, bag filters play a critical role in maintaining air and water quality in industrial settings.

Exploring Bag Filter Types

In industrial applications, several types of bag filters are available, each designed for specific filtration requirements. Below are some of the most common bag filter designs:

| Bag Filter Type | Features | Benefits |

|---|---|---|

| Pulse Jet Bag Filters | Uses pulses of compressed air to clean filter bags, suitable for high flow rates, and sticky/dusty products. | Low compressed air usage, high filtration efficiency, reduced maintenance costs. |

| Reverse Air Bag Filters | A cleaning system using a reverse airflow, suitable for high temperatures, and sticky/dusty products. | Low compressed air usage, longer bag life, and reliable performance at high temperatures. |

| Shaker Bag Filters | Uses a shaking mechanism to remove dust from the filter, suitable for low to medium flow rates, and coarse particulates. | Low capital cost, straightforward design, and easy maintenance. |

It’s essential to consider the features and benefits of each bag filter type to determine the most suitable type for your industrial application. A properly selected and installed bag filter type can help achieve maximum filtration efficiency and maintain a cleaner and safer working environment.

Bag Filter Design and Functionality

Bag filters are critical for industrial filtration, as they capture and remove impurities from gas or liquid streams. A well-designed bag filter system can help ensure optimal performance, efficient operation, and extended longevity.

Housing

Bag filter housing is an important component as it protects the filter bags and provides a sealed chamber for the filtration process. Bag filter housing can be constructed with different materials, such as plastic or metal, depending on the operating conditions and filtration requirements.

Filter Bags

Filter bags are the main filtration media and come in a variety of materials, shapes, and sizes to accommodate different applications. Filter bag selection is crucial to maximize the filtration efficiency and to ensure that the bag filter performs optimally.

Inlet and Outlet Connections

The configuration of the inlet and outlet connections can influence the efficiency and performance of the bag filter. Adequate connections and fittings are necessary for proper installation, effective filtration, and easy maintenance.

Cleaning Mechanisms

Bag filters require cleaning mechanisms to maintain their filtering capacity and efficiency. There are different cleaning methods available, from manual cleaning to automated systems, each with its unique benefits and drawbacks. The cleaning mechanisms must be selected based on the type of filter media and the operating conditions.

Overall, the design and functionality of bag filters play a crucial role in effective industrial filtration. Proper design, material selection, adequate connections, and cleaning mechanisms are all essential factors to ensure optimal bag filter operation and maximum filtration efficiency.

Key Factors for Bag Filter Efficiency

Bag filtration systems are essential in maintaining air and liquid quality in various industrial applications. To ensure the optimal performance of bag filters, it’s crucial to understand the key factors that contribute to their efficiency. Here are some of the critical factors to consider:

Filtration Velocity

The filtration velocity refers to the speed at which the air or liquid passes through the bag filter system. Higher filtration velocities can lead to reduced filter efficiency, while lower velocities can cause system pressure drop. It’s essential to maintain optimal filtration velocities by adjusting the filter size and cleaning mechanisms accordingly.

Filter Media Selection

The filter media plays a critical role in bag filter performance. It’s essential to select filter media that can trap the specific impurities present in the air or liquid stream effectively. Factors such as particle size, chemical composition, and operating conditions should be considered when choosing the filter media.

Operating Conditions

The operating conditions of the bag filter system can significantly impact its efficiency. Factors such as temperature, humidity, and air pressure can affect filter media permeability and cause system clogging. It’s crucial to monitor and maintain optimal operating conditions to ensure bag filter efficiency.

Regular Maintenance

Regular maintenance is key to extending the life and performance of bag filters. It’s important to follow proper cleaning procedures, replace worn-out filter bags, and monitor system performance regularly. Neglecting maintenance can cause an increase in energy consumption, clogging of the system, and a decrease in filtration efficiency.

| Factors to Consider | Impact on Bag Filter Efficiency |

|---|---|

| Filtration Velocity | Higher velocities lead to reduced filter efficiency, while lower velocities can cause system pressure drop. |

| Filter Media Selection | The filter media plays a critical role in bag filter performance. It’s essential to select filter media that can trap the specific impurities present in the air or liquid stream effectively. |

| Operating Conditions | The operating conditions can significantly impact bag filter efficiency. Factors such as temperature, humidity, and air pressure can affect filter media permeability and cause system clogging. |

| Regular Maintenance | Regular maintenance is key to extending the life and performance of bag filters. It’s important to follow proper cleaning procedures, replace worn-out filter bags, and monitor system performance regularly. |

By optimizing these critical factors, bag filter efficiency can be enhanced, providing more robust and reliable filtration performance. Proper maintenance and monitoring of the system can extend the life of the filter, reduce energy consumption, and prevent costly system failures.

Importance of Bag Filter Maintenance

Regular maintenance of bag filters is crucial to ensure their efficient operation and longevity. Improper maintenance can lead to various issues such as clogged filters, reduced airflow, higher operational costs, and decreased filtration efficiency. Therefore, it’s essential to follow maintenance best practices for bag filter systems.

The following are some guidelines that can help maintain bag filter systems:

- Inspect filter bags regularly to check for any signs of wear and tear.

- Replace filter bags after a specific timeframe or when the differential pressure across the filters exceeds the recommended values.

- Clean bag filters periodically to remove any accumulated particulate matter and ensure optimum airflow.

- Check the cleaning mechanism, such as pulse jets, for any malfunction and repair or replace if necessary.

- Ensure that the bag filter housing is properly sealed to prevent any leakage of the filtered material.

Following these maintenance guidelines can help extend the life of bag filter systems and minimize downtime and maintenance costs.

Bag Filter in Pharmaceutical Engineering

Pharmaceutical manufacturing facilities require high levels of air quality to prevent contamination during the production process. Bag filters play a critical role in maintaining clean air in such environments by capturing and removing particles from the air, including bacteria and viruses. Bag filters are versatile and can be used in various areas of pharmaceutical engineering, including:

- Manufacturing and packaging zones

- Cleanrooms and sterile areas

- Research labs and quality control facilities

Benefits of Bag Filters in Pharmaceutical Engineering

- Reduces the risk of contamination and infection by capturing and removing hazardous particles from the air

- Improves product quality by ensuring a clean environment during the production and packaging process

- Protects the health and safety of employees by removing harmful chemicals and microorganisms from the air

- Increases efficiency and productivity by providing a controlled and optimized environment for drug manufacturing

Proper maintenance of bag filters is crucial to ensure optimal performance and effectiveness. Regular cleaning and replacement of filter bags are essential to prevent clogging and maintain air quality standards.

Bag Filter in Boiler Systems

In industrial settings, boilers are used to generate steam or electricity. However, the process produces flue gases that contain fly ash and other particulate matter, which can pollute the air if left unfiltered. To address this issue, bag filters are installed in boiler systems to capture and remove these contaminants.

Bag filters operate on the principle of microfiltration, using a series of filter bags to trap particles as flue gases flow through them. The bags are made of high-quality filter media that can retain particles as small as a few microns, ensuring efficient filtration.

The benefits of using bag filters in boiler systems are significant. By removing particulate matter from flue gases, bag filters help to reduce air pollution, improving the quality of the air in manufacturing facilities and surrounding areas. Additionally, bag filters contribute to improved energy efficiency by maintaining clean boiler surfaces, which enhances heat transfer and reduces fuel consumption.

Integrating bag filters into boiler systems is a cost-effective and practical solution for reducing air pollution. By choosing the right type of bag filter for specific requirements, industries can ensure that their boiler operations are efficient, environmentally friendly, and compliant with regulations.

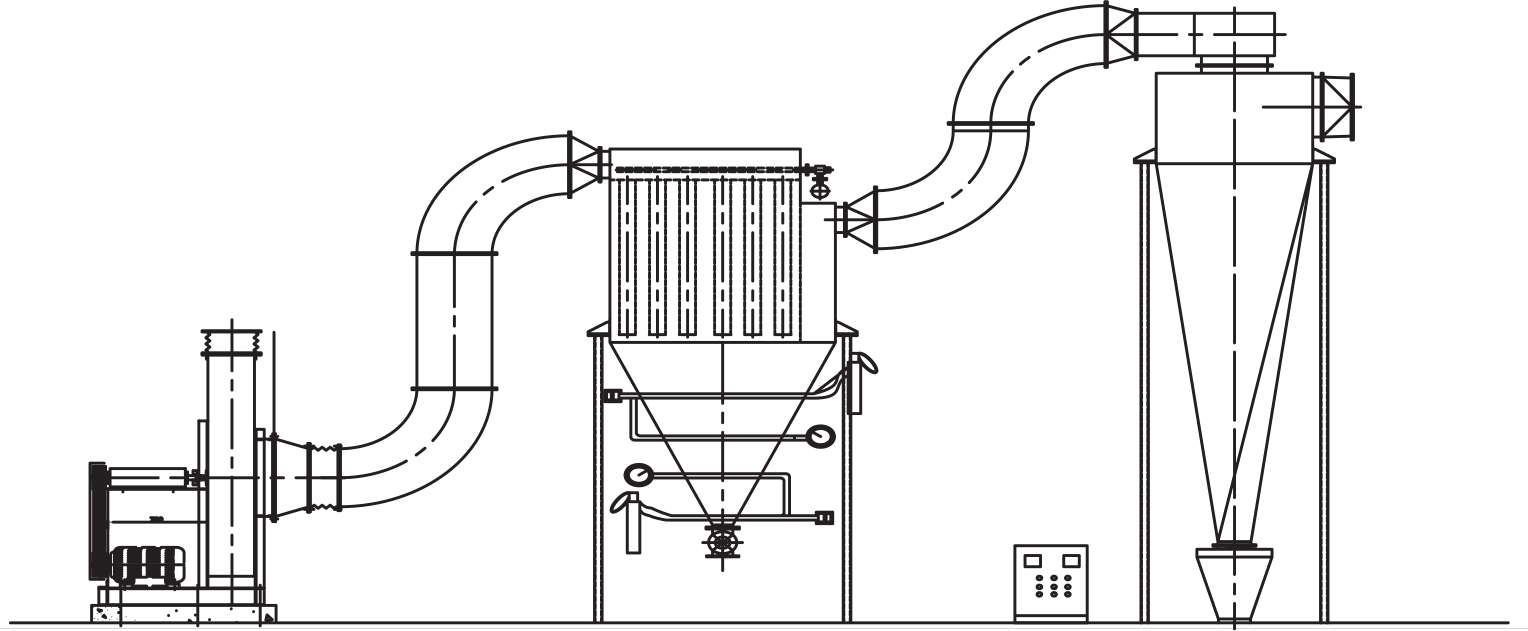

Bag Filter Diagram for Easy Understanding

In this section, we offer a visual representation of a typical bag filter system through a detailed bag filter diagram. Designed to exhibit the entire flow path and components of a bag filtration system, the diagram is a demonstrative complement to the earlier sections of the guide on bag filters. It illuminates the components of a bag filter system and presents an intuitive explanation to provide an easy grasp of the mechanisms at work.

Bag Filter Diagram:

The bag filter diagram is organized to showcase the following fundamental components of a typical bag filtration system:

- Air or liquid medium contaminated by particulate matter enters the bag filter.

- The filter inlet collects the contaminated medium, which passes through the filter media bag.

- The bag filters the contaminated medium, retaining impurities with the bag fibers and releasing the purified medium out the exhaust outlet.

- The deprived bag filter requires cleaning to flush out retained particulate matter before proceeding with subsequent filtration rounds.

- The dislodged particulate matter gets collected in an ash bin, hopper, or any designated container for disposal.

The above mentioned details offered by the bag filter diagram significantly contribute to a well-rounded understanding of bag filtration systems. It further serves as a useful guide to bring about quality outcomes in industrial environments and enhances efficiency.

Bag Filter Price and Considerations

Bag filters are an essential tool for industrial filtration, but they come at a cost. The price of a bag filter system varies depending on several factors.

The initial investment for a bag filter system includes the cost of equipment, installation, and commissioning. This amount varies based on the size and capacity of the filtration system.

Maintenance expenses are another critical consideration for bag filter systems. Routine maintenance is necessary to ensure the system operates at optimum efficiency, and the cost of regular maintenance must be factored into the overall cost.

Additional operational expenses to consider when implementing bag filter systems include energy consumption, bag replacement, and disposal costs.

While bag filter systems require an initial investment and ongoing maintenance costs, they can provide significant benefits, including improved air quality, reduced emissions, and a cleaner working environment for employees. So, when considering the cost of a bag filter system, it’s important to weigh the expenses against the benefits and choose a cost-effective solution that aligns with your filtration requirements.

Factors Influencing Bag Filter Price

| Factors | Impact on Price |

|---|---|

| System capacity and size | Higher capacity systems typically require larger housing, more filter bags, and more robust cleaning mechanisms, leading to increased costs. |

| Filter media selection | The type and quality of filter media significantly affect the price. High-performance materials are more expensive than standard media. |

| Cleaning mechanism | Cleaning mechanisms can range from manual shaking to automatic pulse-jet cleaning. Automated systems are more expensive but require less maintenance. |

| Maintenance requirements | The complexity and frequency of maintenance tasks impact the cost of operating a bag filter system. More advanced systems typically require more frequent maintenance. |

| Location and installation requirements | The location and installation requirements can impact the cost of implementing a bag filter system. Access, space, and safety considerations can all contribute to additional expenses. |

Depending on these factors, the price of a bag filter system can range from a few thousand dollars to hundreds of thousands of dollars. Whatever the cost, it’s essential to evaluate the benefits of a bag filter system and ensure that the system’s investment aligns with operational requirements, maintenance costs, and long-term savings.

Bag Filter Uses and Benefits

Bag Filters are versatile and widely used across various industries due to their numerous benefits.

Uses

Bag filters are used for a range of applications including:

- Particulate and dust emissions control in air pollution control systems

- Fume and particulate filtration in industrial processes such as cement, mining, and food processing

- Clean-room applications in the pharmaceutical industry

- Fly ash and other particulate removal from flue gas streams in boiler systems

Benefits

Bag Filters offer a host of benefits including:

- Improved air quality: Bag filters remove pollutants and particulate matter from gas and liquid streams, resulting in cleaner air and safer working environments.

- Reduced emissions: Bag filters contribute to reduced emissions of harmful gases and particulates, minimizing the impact on the environment.

- Enhanced product quality: The use of bag filters in manufacturing processes results in cleaner products, ensuring higher quality and purity.

- Increased process efficiency: Bag filters help maintain consistent air and liquid flow rates, optimizing process efficiency.

- Cost-effective: Bag filters have lower initial investment and operating costs compared to other filtration methods, making them an affordable solution for many industries.

“Bag filters play a vital role in a range of industrial processes, contributing to improved air quality, reduced emissions, and enhanced product quality.”

Conclusion

Bag filters play a crucial role in maintaining a clean and safe industrial environment. In this ultimate guide to bag filter types, function, and efficiency, we have covered the essential aspects of bag filters, including their working principle, design, and maintenance.

Readers have gained insights into different bag filter types, their features, and benefits. They have learned about the factors that affect bag filter efficiency, such as filter media selection, operating conditions, and maintenance. Moreover, we have discussed the specific applications of bag filters in pharmaceutical engineering and boiler systems.

Implementing bag filter systems may involve a significant investment, but the benefits they offer, such as improved air quality, reduced emissions, and enhanced product quality, make them a wise choice for any industrial process.

We hope that this guide has provided readers with a comprehensive understanding of bag filters and their role in optimizing filtration performance. By following the best practices and guidelines outlined in this guide, readers can ensure the longevity and reliability of their bag filter systems, contributing to a cleaner and safer working environment.

About Author

Filter Concept Private Limited is the leading industrial filters & cartridges manufacturer, exporter, and supplier! We are delighted to be your go-to source for filtration solutions for all your demanding applications of air, gas and liquid filtration. Based in Ahmedabad, the commercial hub of India, we offer an extensive range of products that includes Industrial Dust Collection system, cartridge filter housing, bag filter housing, basket filter housing, self-cleaning filters, filter cartridges, filter bags, and more. Our team of experts has decades of experience working with the best-in-class filtration technologies that ensure unparalleled performance and reliability.

We are committed to delivering the highest quality products and services to our customers. Our dedication to meeting customer expectations is what sets us apart from the competition and has earned us a reputation as the go-to source for industrial filtration. At Filter Concept Private Limited, we understand that your filtration needs are unique. That’s why we offer customized solutions and use our knowledge and expertise to tailor every solution to your specific needs. We invite you to explore our complete range of filtration solutions and let us be your trusted partner for all your filtration needs.