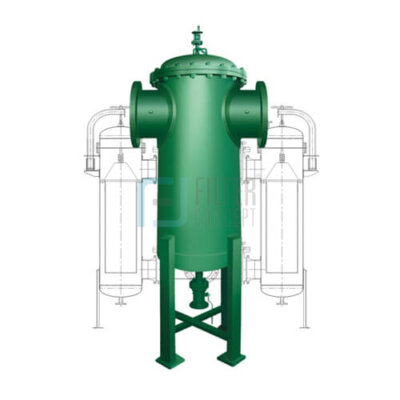

Basket Filter & Strainers

Basket filters & strainers permit the straining & filtering of a wide variety of fluids and retain solid components of almost any size. All baskets are easily removable &easy-to-clean. Basket strainer elements can be offered in single cylinder, double cylinder, multi cylinder & pleated

depending upon the requirement of the application. They are constructed with the filter housing, filter element supported with perforated cage, and positive sealing arrangement to avoid any bypass & choice of end connections.

Operation

Unfiltered liquid enters the basket housing and passes down through them. Solids are retained inside / outside of the basket depending upon design and are removed when the unit is serviced.They are available with an instu backwashing arrangement, wherein removal of baskets for cleaning is not required often.

the basket filters & strainers are normally supplied with a spring arrangement at the top of filter element. This will ensure any type of bypassing & confirm the position of basket, even in case of reverse flow. Fluid bypass around the basket is prevented by an optional O’-Ring seal between the basket rim and the housing inside diameter.

- Features & Benefits

- Duplex Basket Filter & Strainers

- Technical Specifications

- Applications

- Product Code Abbreviation

- Large-area, heavy–duty baskets.

- Low pressure drops.

- Housing are permanently piped.

- Covers are O’-Ring sealed.

- Carbon steel, or stainless steel (304 Or 316) housing.

- Easy to clean.

- Option of insitu backwashing.

- Filtration rating available from 5 micron to 2000 micron & more.

- ASME code stamp available.

- High pressure rating design available.

- Flow rate up to 2000 m3/hr & More.

- Customized design available.

- All housings made from SS 316 L, SS 316 & SS304 are mirror polished to resist adhesion of dirt and scale.

- Carbon steel housings are sand blasted, Epoxy coated & finally painted with two coats of synthetic enamel.

- Liquid displacers for easier servicing.

- Duplex / Triplex & Jacketed units available.

- High temperature & high pressure design are available.

- Normally designed for free flow area through screen, 4 – 6 times pipe flow area.

- Choice of basket filter elements.

- Single cylinder design

- Double cylinder design

- Multi cylinder design

- Pleated element design available for low pressure drop & high dirt hold

Duplex basket filter & strainer permits continuous operation because flow can be switched back and forth between two filter sections. This allows one side to be serviced while the other is in use. Normally duplex basket filters are separated with three way ball valves or two way ball valve/ butterfly valve connected with equalization tee, between two baskets filter housing.

Sizes

- 1” Line Size To 24” Line Size & More

Flow Rate

- Capacity: Up to 2000 m3 /hr & More

Material of construction

- SS 316L

- SS 316

- SS 304

- SS Duplex

- CARBON STEEL (ALL GRADE)

- MILD STEEL

- ALLOY METALS

- POLYPROPYLENE

- LEAD LINING with Any Metal

- RUBBER LINING with Any Metal

- PTFE LINING with Any Metal

Basket element design available

- Single Cylinder Design

- Double Cylinder Design

- Multi Cylinder Design

- Pleated Element Design

Gasket / O’ Ring Material

- Neoprene

- Nitrile

- Silicone

- Viton

- Buna N

- EPDM

- PTFE

Choice of valve available

- Two way Ball Valve

- Three Way Ball Valve

- Butterfly Valve

End Connections Available

- NPT / BSP Threaded

- Flanged Table E / Table F

- ANSI B 16.5 Flanged

- DIN Standard

- Tri Clover Adaptors

- SMS /Dairy End Connection

| Power Plant |

| Process Industries |

| Cement Plant |

| Steel |

| Petrochemicals |

| Fertilizers |

| Refineries |

| Oil & Gas |

| Chemicals |

| Textiles |

FCIBF-S11-M-WWW-100150450-D

| FCI | BF | Style | Material | Construction | Size | Design |

|---|---|---|---|---|---|---|

| Basket Filter Housing | S11 – Style – 1 – < 100 Micron – Good Manufacturing Practice | A-SS 304 | WWW – Wire Mesh Wrap Round Welded | 100 – Connection Size | Duplex | |

| S12 – Style – 1 – > 100 Micron – Good Manufacturing Practice | B-SS 316 | WPW – Wire Mesh Pleated Welded | 150 – Diameter Of Element | Simplex | ||

| S21 – Style – 2 – < 100 Micron – ASME Sec VIII Div-1 | C-SS 316 L | 450 – Length Of Element | ||||

| S22 – Style – 2 – > 100 Micron – ASME Sec VIII Div-1 | D-CARBON STEEL | |||||

| E-CSRL | ||||||

| F-ASTM A 106 | ||||||

| G-ASTM A 517 | ||||||

| H-ASTM A 516 |