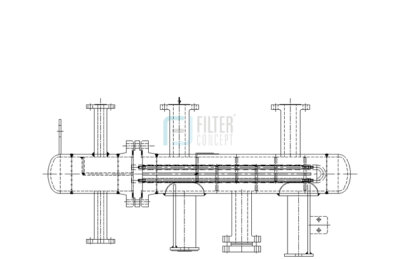

Heat Exchangers (Shell & Tube)

Heat exchangers are designed to transfer heat between fluids like liquids, vapours, or gasesof different temperatures. Exchange or transfer of heat is done through a solid separator to avoid mixing of heat-transfer agents or prevent their contact.

In industries, they are widely used for cooling as well as heating in large scale processes. Dimensions of heat exchangers are designed to match thermodynamic requirements of client.

Heat exchangers are designed as per Construction Code ASME Sec. VIII Div. I in accordance with ASME, TEMA, ANSI, API 660, ROHS, GOST, NORSOK, CE and other relevant codes.

Size: 6” diameter & above

Types:

- Single pass

- Multiple pass

- Single flow

- Multiple flow

- Kettle type -Fixed tube sheet

- Kettle type – Floating tube sheet

- Straight

- U-tube bundles

Carbon Steel, Stainless Steel, Alloy Steel and other MOC

Material of construction:

- ASTM A 561 GR 60, 65 & 70

- ASTM A 240 GR 304, 304L, 316, 316L

- ASTM A 106 GR B

- ASTM A 312 TP 304, TP 304L, TP 316, TP 316L

- Cu/Ni (90/10 & 70/30)

- Oil & Gas

- Chemicals

- Refrigeration

- Petrochemicals

- Pharmaceuticals

- Power

- Food & Beverage