A coalescing filter is key in many industrial systems. It separates liquids from gases or other liquids to keep operations clean. Knowing about the different types and how they work is important for improving processes in places like factories and energy plants. This article explains what a coalescing filter is, why it matters, and how it’s used in real life. It shows how these filters help make industrial work more efficient and effective.

Key Takeaways

- Coalescing filters are vital for improving operational efficiency across various industries.

- They effectively separate liquids from gases, enhancing process clarity.

- Understanding the different coalescing filter types is crucial for application-specific utilization.

- The working principle involves specialized mechanisms to achieve optimal filtration.

- Real-world applications span from industrial manufacturing to oil and gas sectors.

Understanding Coalescing Filters

Coalescing filters are key in making fluids and gases cleaner by removing contaminants. They work by combining small droplets into bigger ones. This makes it easier and more efficient to separate them.

In industries, keeping things pure and running smoothly is vital. Coalescing filters help a lot by getting rid of unwanted stuff in fuels and oils. This makes systems more reliable and saves on maintenance costs.

So, why is coalescence so important? It makes it easier to remove small droplets and boosts system performance. Every successful separation helps systems last longer and products get better, making coalescing filters essential in many fields.

What Is a Coalescing Filter?

A coalescing filter is key in many industries. It removes liquid water and particles from gas and oil streams. Knowing about coalescing filters helps us see their importance in keeping processes running smoothly and products top-notch.

In fields like oil and gas, aerospace, and manufacturing, these filters stop corrosion and contamination. This helps keep operations running well.

Definition and Overview

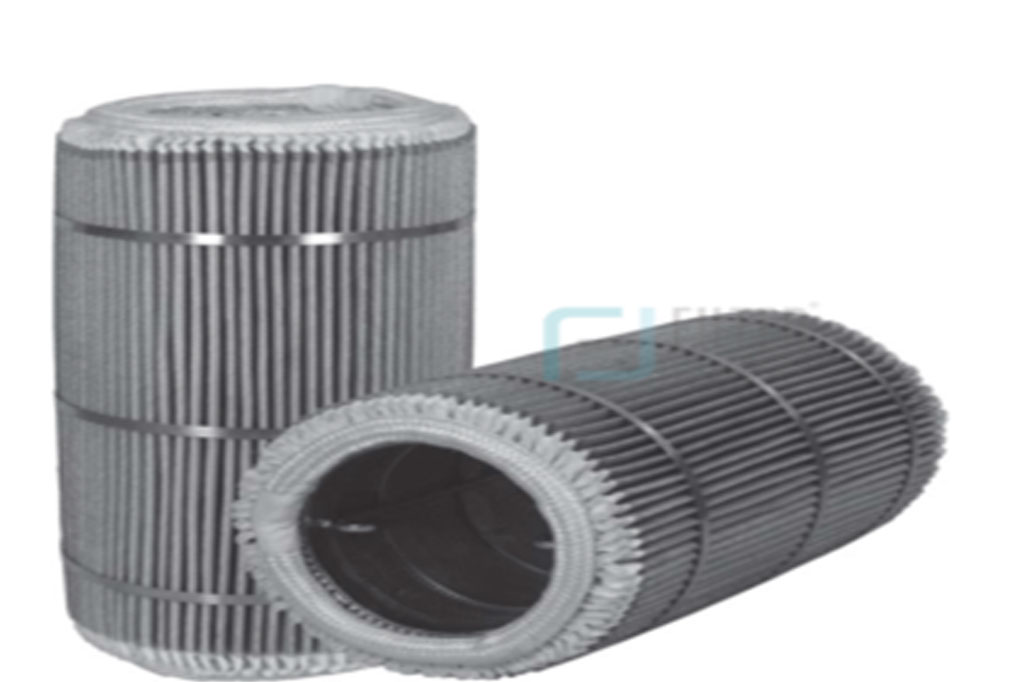

A coalescing filter combines small liquid droplets in gas or oil into bigger ones. This makes it easier to remove contaminants, leading to cleaner products. These filters use special media to catch particles, helping separate liquids and solids efficiently.

Importance in Industrial Applications

The role of a coalescing filter is huge. It helps machines last longer and keeps industrial work running smoothly. By protecting equipment from harmful substances, these filters prevent costly breakdowns.

Companies using coalescing filters see better efficiency, quality, and a stronger market position.

Types of Coalescing Filters

It’s important to know the different coalescing filter types for the right choice. Each type tackles unique filtration challenges. This section explores coalescing filters for air compressors, oil, and natural gas, highlighting their functions and comparisons.

Coalescing Filters for Air Compressors

A coalescing filter for air compressors removes moisture and particles. It keeps compressed air systems running smoothly. These filters help equipment last longer and improve air quality in industries.

Coalescing Filters for Oil

Coalescing filters for oil separate water from petroleum. This improves oil quality for further use. They prevent damage and save costs, essential in car and manufacturing sectors.

Coalescing Filters for Natural Gas

Coalescing filters for natural gas remove water and particles. This is key for safe and efficient gas use. Good filtration ensures gas meets standards and keeps supplies reliable.

Comparative Analysis of Different Types

| Filter Type | Primary Function | Typical Applications | Maintenance Requirements |

| Coalescing Filter for Air Compressor | Removes moisture and particulates | Industrial air systems | Regular element changes needed |

| Coalescing Filter for Oil | Separates water from oil | Oil refineries, automotive | Periodic evaluation and replacements |

| Coalescing Filter Natural Gas | Removes contaminants from gas | Natural gas pipelines | Routine inspections critical |

Working Principle of Coalescing Filters

The coalescing filter works by using the natural process of coalescence. This is when small liquid droplets join to form bigger ones. This helps separate contaminants from the main fluid stream. Knowing how coalescence happens is key to understanding how coalescing filters work well in many fields.

How Coalescence Works

Coalescence happens when small droplets meet and merge. This makes the liquid separation process more efficient. The bigger droplets that form can then be easily taken out of the fluid, improving filtration. This method is very useful in industries that need very clean products, like pharmaceuticals and food processing.

Separation Mechanisms Explained

The main ways coalescing filters separate things include gravity settling and centrifugal forces. Gravity settling lets bigger droplets fall away from the fluid because of their weight. Centrifugal forces help this happen even more in systems that spin. Both of these are important for getting the right separation between contaminants and the fluid.

| Separation Mechanism | Description | Application |

| Gravity Settling | Uses density differences to let larger droplets fall and separate from the fluid. | Water treatment, oil refining |

| Centrifugal Force | Uses rotation to make droplets separate from the fluid more efficiently. | Industrial liquid processing, wastewater management |

Benefits of Using a Coalescing Filter

In industrial operations, coalescing filters offer many advantages. They boost process efficiency, enhance product quality, and save costs. Knowing these benefits helps businesses make smart choices for reliable filtration.

Enhancing Process Efficiency

Coalescing filters are great for improving process efficiency. They cut down on downtime and keep systems running smoothly. This leads to better productivity and fewer interruptions.

Improving Product Quality

These filters also play a big role in product quality. They stop contaminants like water and dirt from damaging equipment and products. This ensures products meet high standards and customer expectations.

Cost-Effectiveness and Maintenance

Another big plus is the reduced maintenance needs. Coalescing filters keep equipment clean longer, reducing the need for repairs. This makes them a cost-effective choice for businesses.

| Benefit | Description |

| Process Efficiency | Reduces downtime and enhances productivity. |

| Product Quality | Helps maintain high standards by filtering out impurities. |

| Cost-Effectiveness | Decreases maintenance needs and extends equipment lifespan. |

Coalescing Filter vs Particulate Filter

It’s important to know the differences between filters for industrial use. A coalescing filter removes liquid contaminants like water from gases or fluids. This is key for keeping systems running well.

A particulate filter, on the other hand, catches solid particles. It’s great at getting rid of dust and dirt. This is essential in keeping places clean, especially in factories.

Looking at coalescing vs particulate filters shows their unique roles. Coalescing filters handle liquids, while particulate filters deal with solids. Choosing the right filter is critical for keeping equipment in top shape.

Real-World Applications of Coalescing Filters

Coalescing filters are key in many fields, boosting efficiency and keeping systems clean. They remove harmful particles, making them crucial in industries like manufacturing and energy. Their role is vital for keeping processes running smoothly.

Industrial Manufacturing

In industrial settings, coalescing filters protect sensitive machines from dirt. They keep lubrication systems and hydraulic fluids clean, helping machines last longer. Their use in manufacturing shows how important they are for keeping things running well and products of high quality.

Aerospace and Automotive Industries

The aerospace and automotive fields rely on coalescing filters to keep fuel systems clean. They remove water and other harmful substances, preventing corrosion and ensuring engines work at their best. In these industries, good filtration is key to safety and performance.

Oil and Gas Sector Uses

In the oil and gas industry, coalescing filters are essential for keeping things safe and efficient. They remove free water and solids from fuels, protecting equipment and meeting strict standards. Their role in this sector is clear, showing how important they are for safeguarding resources.

What Are the Benefits of a Coalescing Separator?

Coalescing separators offer big advantages for many industries. They improve efficiency and protect the environment. These tools help remove impurities and make systems work better, leading to a greener future.

Long-Term Operational Advantages

Coalescing separators cut down on downtime. They keep fluids clean, making machines run smoothly and reliably. This means less chance of expensive breakdowns.

They also extend the life of equipment by stopping damage from dirt. Companies can work more efficiently, leading to better productivity and profits.

Environmental Impact Reduction

Coalescing separators are key to saving the environment. They filter out pollutants before they harm the air or water. This helps meet environmental rules and fights pollution.

Using these separators shows a commitment to protecting our planet. It helps keep our world clean for the next generations.

Pricing Factors for Coalescing Filters

The cost of coalescing filters varies due to several factors. Knowing these factors helps you make better choices. The type of filter and the needs of different industries play big roles in pricing.

Cost Variability Among Different Types

Prices for coalescing filters change based on their use. For example, air compressor filters might cost more than those for oil or gas. The brand also affects the price. Well-known brands usually charge more because they are reliable.

Factors Influencing Coalescing Filter Price

Many things impact the cost of coalescing filters:

- Filter Materials: Better materials cost more but last longer and work better.

- Flow Capacity: Filters that handle more air or liquid cost more but can do more.

- Maintenance Requirements: Filters needing less upkeep might be pricier but save money in the long run.

- Application-Specific Features: Special features for certain industries can also raise the price.

Difference Between Coalescing and Multifocal Filters

Coalescing filters remove water and particles from liquids or gases. They are key in many industrial processes. This makes them vital for ensuring substances are pure and meet quality standards.

On the other hand, multifocal filters are used in optical systems. They manage light to create different focal points. This is important for cameras and telescopes to get clear images at various distances.

This shows a big difference between coalescing and multifocal filters. Coalescing filters improve fluid performance in industries. Multifocal filters, however, deal with light in optical systems. Knowing these differences helps choose the right filter for each need.

Conclusion

Coalescing filters are key in many industrial processes. They make things work better and improve product quality. They help clean oil, gas, and air systems, making them run smoother.

These filters also cut down on maintenance costs and reduce downtime. This is great for keeping things running smoothly and efficiently.

Coalescing filters are used in many areas, showing how important they are. They help keep things safe and protect the environment. By using these filters, industries can do better and stay safe.

Choosing good coalescing filters helps businesses do their best. It makes sure everything runs well and safely.

FAQ

What is a coalescer used for?

Coalescers are used to separate water from fuels, oils, and gases. They are key in oil and gas, manufacturing, and aerospace. They keep products clean and prevent damage.

Why is coalescence important?

Coalescence is key because it helps small droplets of contaminants merge. This makes them easier to separate from fluids. It ensures cleaner processes and safety in industries.

What is the role of coalescing filters in air compressors?

Coalescing filters in air compressors remove moisture and particles. This improves performance, reduces wear, and lowers maintenance costs. It’s great for compressor applications.

How do coalescing filters work with oil?

Coalescing filters for oil separate water from petroleum products. This prevents corrosion and keeps oil quality high. It’s vital for many industrial operations.

Can coalescing filters be used for natural gas?

Yes, coalescing filters for natural gas remove liquid contaminants. This ensures the gas is pure and safe for use. It’s important for combustion and energy production.

What is the difference between coalescing and particulate filters?

Coalescing filters target liquid contaminants by merging and separating them. Particulate filters capture solid particles. Knowing this difference helps choose the right filter for specific needs.

What factors influence the price of coalescing filters?

The price of coalescing filters varies based on type, material, flow capacity, and maintenance needs. These factors affect the cost for different industrial uses. It’s important to consider them when buying.